trolling motor wiring guide

Proper trolling motor wiring is essential for safety and performance. Understanding circuit breakers, plugs, and fuses ensures reliable operation. Follow guides for voltage-specific setups to avoid damage and optimize efficiency.

1.1 Overview of Trolling Motor Systems

A trolling motor system is a critical component for controlled boat movement, especially in fishing scenarios. These systems typically include a motor, control unit, and power source, often consisting of deep-cycle batteries. The motor operates at various voltages, such as 12V, 24V, or 36V, depending on the model and application. Proper wiring ensures efficient power delivery and safety. Key components like circuit breakers, fuses, and quick-disconnect plugs are essential for protecting the system from overcurrent and enabling easy maintenance. Understanding the system’s layout and voltage requirements is vital for optimal performance and longevity. Always consult wiring diagrams specific to your motor’s voltage to avoid damage or safety hazards. Regular checks and proper handling of electrical connections are crucial to prevent issues like wire degradation or battery drain. A well-maintained trolling motor system enhances your boating experience and ensures reliability on the water.

1.2 Importance of Proper Wiring

Proper wiring is crucial for the safe and efficient operation of a trolling motor. Incorrect wiring can lead to electrical hazards, damage to components, and even fire risks. It ensures that the motor operates at the correct voltage, preventing overheating and premature wear. Proper connections also minimize interference with other boat electronics, such as fish finders or radios. Additionally, correct wiring enhances the overall performance of the trolling motor, providing consistent power delivery and reliable control. Safety is a top priority, as faulty wiring can pose serious risks, especially in marine environments. Following established guidelines and using the right materials, like appropriate wire gauges and circuit protection devices, ensures a secure setup. Regular inspections and maintenance of wiring are essential to uphold safety standards and maintain optimal functionality. Proper wiring practices not only protect your investment but also contribute to a safer and more enjoyable boating experience.

Essential Components of Trolling Motor Wiring

Essential components include circuit breakers, plugs, receptacles, fuses, and inline fuse holders, ensuring safe and reliable power distribution for optimal trolling motor performance.

2.1 Circuit Breakers and Their Role

Circuit breakers are crucial for protecting trolling motor systems from overcurrent conditions. They act as safety devices, interrupting the power supply if excessive current flows, preventing damage or fire hazards. Circuit breakers also serve as convenient switches for turning the trolling motor on or off. Proper installation involves mounting them close to the motor to minimize wire length, reducing voltage drop. Using the correct wire gauge, such as 6 AWG for shorter runs, ensures reliable performance. Circuit breakers protect both the motor and battery, ensuring safe operation. They are essential for maintaining electrical integrity and preventing potential risks. Always choose a circuit breaker rated for your system’s voltage and current requirements. This ensures optimal protection and functionality, safeguarding your investment and ensuring a trouble-free boating experience.

2.2 Plugs and Receptacles for Quick Disconnect

Plugs and receptacles are essential for quick disconnect functionality in trolling motor wiring. They allow easy removal of the motor for storage or service, enhancing convenience and safety. These connectors are designed to handle high currents and voltages, ensuring reliable power transfer. Proper selection based on wire gauge and system voltage is critical to prevent overheating or electrical issues. Shielded plugs and receptacles can reduce interference, especially in systems with advanced sonar or GPS features. Regular inspection and maintenance of these connectors are vital to ensure secure connections and prevent corrosion. Using high-quality plugs and receptacles from reputable brands like MotorGuide or Minn Kota ensures durability and performance. They are a key component in maintaining a safe and efficient trolling motor system, offering peace of mind during operation. Always follow manufacturer guidelines for installation and care to maximize their lifespan and functionality.

2.3 Fuses and Inline Fuse Holders

Fuses and inline fuse holders are critical components in trolling motor wiring, providing essential protection against overcurrent and electrical surges. They act as a safety barrier, preventing damage to the motor, batteries, and wiring in case of a short circuit or overload. Properly sized fuses ensure that the system remains protected without interrupting normal operation. Inline fuse holders offer convenience, allowing easy access for fuse replacement without dismantling the entire wiring setup. For most trolling motors, a 30A or 40A fuse is sufficient, but this depends on the motor’s peak current draw. Always use high-quality fuses and holders rated for marine environments to withstand corrosion and moisture. Mounting the fuse holder close to the battery helps protect the entire circuit. Regular inspection of fuses and holders is recommended to ensure reliability and safety. Consult your motor’s manual for specific fuse size recommendations to avoid under or over-protection of your system.

Wiring Diagrams for Different Voltages

Wiring diagrams for 12V, 24V, and 36V systems ensure proper connections and safety. Each voltage requires specific configurations to match motor and battery setups, preventing damage and optimizing performance.

3.1 12V Trolling Motor Wiring Diagram

A 12V trolling motor wiring diagram provides a clear layout for connecting components. It typically includes a single deep-cycle battery, circuit breaker, and motor. The positive battery terminal connects to the circuit breaker, which then links to the motor’s positive input. The negative terminal of the motor attaches directly to the battery’s negative side. This setup ensures safe and efficient power delivery. Proper wire gauge, such as 8AWG or 6AWG, is crucial to prevent overheating; Always disconnect the battery before wiring to avoid electrical hazards. Following the diagram ensures optimal performance and minimizes risks. Consult the motor’s manual for specific recommendations, as configurations may vary slightly by brand or model. Correct wiring is essential for longevity and reliability of the trolling motor system.

3.2 24V Trolling Motor Wiring Diagram

A 24V trolling motor wiring diagram involves two 12V deep-cycle batteries connected in series. The positive terminal of the first battery links to the negative terminal of the second, creating a 24V system. The trolling motor’s positive lead connects to the positive terminal of the second battery, while the negative lead attaches to the negative terminal of the first. A circuit breaker is often included, mounted close to the motor for added safety. Proper wire gauge, such as 8AWG or 6AWG, ensures efficient power delivery without overheating. Always use a multimeter to verify battery voltage before connection. Safety precautions, like avoiding jewelry and wearing protective gear, are essential. Following the diagram and manufacturer’s instructions ensures reliable operation and prevents electrical hazards. Correct wiring is vital for optimal performance and longevity of the 24V trolling motor system.

3.3 36V Trolling Motor Wiring Diagram

A 36V trolling motor wiring diagram typically involves three 12V deep-cycle batteries connected in series to achieve the required voltage. The positive terminal of the first battery connects to the negative terminal of the second, and the positive terminal of the second connects to the negative terminal of the third. This configuration ensures a total of 36V. The trolling motor’s positive lead is then attached to the positive terminal of the third battery, while the negative lead connects to the negative terminal of the first. A circuit breaker is essential for safety and should be installed close to the motor. For a 36V system, a heavier wire gauge, such as 4AWG or 2AWG, is recommended to handle the increased power. Always use a multimeter to verify battery voltage and ensure secure connections to prevent electrical hazards. Proper wiring ensures efficient performance and longevity of the 36V trolling motor system.

Battery Configuration and Setup

Proper battery configuration is crucial for trolling motor performance. Series setups increase voltage, while parallel configurations boost capacity. Use deep-cycle batteries for longevity and ensure correct polarity to avoid damage.

4.1 Series Battery Configuration for 24V Systems

Configuring batteries in series is essential for achieving a 24V system. This setup involves connecting the positive terminal of one battery to the negative terminal of another. For a 24V trolling motor, two 12V deep-cycle batteries are typically used. Step 1: Connect the positive terminal of the first battery to the negative terminal of the second battery using a heavy-gauge wire. Step 2: Attach the trolling motor’s positive lead to the positive terminal of the first battery and the negative lead to the negative terminal of the second battery. This configuration ensures the correct voltage is delivered to the motor. Important: Always verify polarity to prevent damage or safety hazards. Using a multimeter to check voltage ensures batteries are properly connected and charged. This method maximizes performance and extends battery life, making it ideal for trolling motors requiring higher voltage.

4.2 Parallel Battery Configuration for Increased Capacity

A parallel battery configuration is ideal for increasing the capacity of your trolling motor system while maintaining the same voltage. This setup is particularly useful for extending runtime without upgrading to a higher voltage motor. How it works: Connect the positive terminals of all batteries together and the negative terminals together. This configuration keeps the system voltage at 12V, 24V, or 36V, depending on the motor, but increases the total amp-hour capacity. For example, two 12V batteries in parallel provide 24V with doubled capacity. This is beneficial for trolling motors that require consistent power over extended periods. Tip: Use batteries of the same type and capacity to ensure balanced performance and longevity. Parallel wiring is a reliable way to enhance your system’s endurance without complicating the setup.

Safety Precautions and Best Practices

Always handle batteries with care, avoiding jewelry that could conduct electricity. Use proper tools and ensure all connections are secure. Install circuit breakers and fuses to prevent overcurrent issues.

5.1 Safety Tips for Handling Batteries

Handling batteries safely is crucial to prevent accidents. Always wear protective gear like gloves and eyewear to shield against acid spills. Ensure the area is well-ventilated to avoid inhaling harmful fumes. Avoid wearing jewelry, as it can conduct electricity and cause shocks. Use a multimeter to check voltage before connections to prevent short circuits. Never leave batteries unattended while charging, and keep them away from open flames or sparks. Regularly inspect batteries for signs of damage or corrosion and replace them if necessary. Properly secure batteries in the boat to prevent movement during operation. Following these guidelines ensures a safer and more reliable trolling motor system.

5.2 Troubleshooting Common Wiring Issues

Troubleshooting wiring issues in trolling motor systems requires attention to detail and a systematic approach. Start by inspecting connections for looseness or corrosion, as these are common causes of malfunction. Use a multimeter to check for voltage drops or short circuits. If the motor fails to operate, verify that the circuit breaker hasn’t tripped or a fuse hasn’t blown. Ensure all wires are correctly sized for the system’s voltage and current requirements, as undersized wires can overheat and cause issues. Consult your wiring diagram to confirm proper connections. If interference occurs, consider using shielded wires or separating power and signal cables. Addressing these issues promptly ensures reliable performance and prevents potential damage to your trolling motor or electrical components.

Tools and Materials Needed

Essential tools include multimeters, wire cutters, crimpers, and screwdrivers. Materials needed are marine-grade wire, circuit breakers, fuses, and heat-shrink tubing for secure, corrosion-resistant connections.

6.1 Recommended Wire Gauge and Type

Choosing the right wire gauge is crucial for safe and efficient trolling motor operation. For a 24V system, a 6 AWG wire is recommended, while a 12V setup typically requires an 8 AWG wire. The gauge depends on the motor’s amperage and the distance between components. Thicker wires (lower gauge numbers) are better for longer runs to minimize voltage drop. Always opt for marine-grade, copper-based wires with durable insulation to withstand harsh marine environments. Avoid using jumper cables, as they are designed for temporary use and may overheat. Proper wire selection ensures reliable performance, prevents overheating, and reduces the risk of electrical fires. Consult your trolling motor’s manual for specific recommendations, as higher-powered motors may require heavier-duty wiring. Using the correct wire gauge and type is essential for both safety and optimal system efficiency.

6.2 Essential Tools for Wiring

Proper tools are vital for a safe and successful trolling motor wiring project. A multimeter is essential for checking voltage and ensuring connections are correct. Wire cutters and strippers are necessary for preparing cables. Crimpers and soldering irons are used for secure connections, while heat shrink tubing protects them from corrosion. Marine-grade connectors and terminals ensure durability in wet environments. A circuit breaker or fuse holder installer is also crucial for safety. Safety gear like gloves and goggles should always be worn. A wiring diagram specific to your system is indispensable for guidance. Invest in high-quality tools to avoid faulty connections and ensure reliability. Proper tools not only simplify the process but also help prevent electrical hazards, making your trolling motor setup safer and more efficient. Always refer to your motor’s manual for tool recommendations tailored to your system’s requirements.

Installation Best Practices

Mount trolling motors close to the bow’s centerline for optimal control. Use high-quality, marine-grade wire and install circuit breakers near the motor for safety and efficiency.

7.1 Mounting the Trolling Motor

Mounting your trolling motor correctly is crucial for optimal performance and safety. Position the motor as close to the bow’s centerline as possible to maintain even control and minimize steering effort. Use a sturdy mounting bracket or quick-release plate for easy removal when not in use or during storage. Ensure the motor is level and securely fastened to prevent vibration or movement while operating. Proper alignment with the boat’s direction is essential for efficient thrust and maneuverability. Always follow the manufacturer’s instructions for specific mounting requirements, as improper installation can lead to poor performance or safety hazards. Regularly inspect the mount for wear or damage to ensure reliability. A well-mounted trolling motor enhances your fishing experience and prolongs the system’s lifespan.

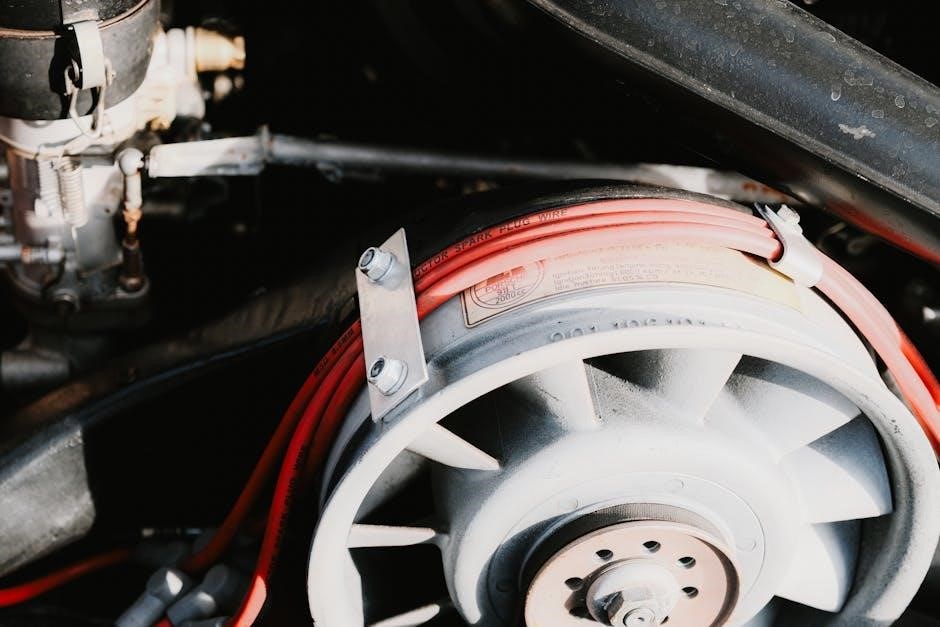

7.2 Routing and Securing Wires

Properly routing and securing wires is critical for a safe and reliable trolling motor installation. Start by planning the wire path to avoid interference with moving parts or exposure to water. Use marine-grade wire and heat-resistant tubing to protect against abrasion and temperature fluctuations. Secure wires with cable ties or adhesive-backed clips, ensuring they are tightly fastened to prevent vibration damage. Keep wires away from sharp edges and heat sources like engines or electronics. Label each wire for easy identification during maintenance or troubleshooting. Avoid tight bends, as they can damage the wire’s insulation. Use grommets or rubber seals when passing wires through surfaces to prevent chafing. Regularly inspect wire connections and securing points to ensure they remain intact and functional. Proper wire management enhances safety, reduces the risk of electrical issues, and prolongs the system’s lifespan.

Maintenance and Upkeep

Regularly inspect wires for damage, clean connections, and apply protective sprays to prevent corrosion. Ensure all components are secure and functioning properly to maintain optimal performance and safety.

8.1 Regular Checks for Wire Integrity

Regularly inspect trolling motor wires for signs of wear, such as fraying, cuts, or corrosion. Use a multimeter to test for continuity and ensure no short circuits exist. Check connections at plugs, receptacles, and battery terminals for tightness and cleanliness. Clean any corrosion using a wire brush and apply a protective coating to prevent future damage. Inspect circuit breakers and fuses to ensure they are functioning correctly. Replace any damaged or worn components immediately to prevent electrical failures. Schedule these checks before each boating season and after exposure to harsh conditions. Proper wire maintenance ensures reliable performance and safety while on the water.

8.2 Cleaning and Protecting Electrical Connections

Clean and protect electrical connections to prevent corrosion and ensure reliable performance. Use a wire brush to remove corrosion from terminals and connectors. Apply a marine-grade protective spray or silicone-based lubricant to shield against moisture and saltwater damage. Avoid using harsh chemicals, as they can degrade materials. Regularly inspect all connections, including plugs, receptacles, and battery terminals, for signs of wear or corrosion. Tighten loose connections to maintain proper conductivity. For added protection, use heat-shrink tubing or electrical tape to seal exposed wires. Clean connections before storing your boat for extended periods to prevent rust buildup. Proper maintenance extends the lifespan of your trolling motor system and reduces the risk of electrical failures while on the water.

Upgrading and Enhancing Your System

Enhance your trolling motor system with advanced components like PWM controllers for better efficiency and lithium batteries for longer runtime. These upgrades improve performance and reliability on the water.

9.1 Adding a PWM Controller

Adding a Pulse Width Modulation (PWM) controller to your trolling motor system offers enhanced control and efficiency. A PWM controller regulates power delivery, reducing heat buildup and extending motor life. It allows for smoother speed transitions and precise throttle control, which is especially beneficial for maintaining steady movement while fishing. Additionally, PWM controllers can improve battery efficiency, reducing overall power consumption. When installing, ensure the controller is compatible with your motor’s voltage and current rating. Mount it in a dry, cool location, and connect it according to the manufacturer’s wiring diagram. Proper installation ensures reliable performance and maximizes the benefits of this upgrade. Always follow safety guidelines to avoid electrical hazards.

9.2 Upgrading to Lithium Batteries

Upgrading to lithium batteries enhances your trolling motor system’s performance and efficiency. Lithium batteries offer longer lifespan, faster charging, and higher energy density compared to traditional lead-acid batteries. They are also lighter, reducing overall boat weight and improving maneuverability. When upgrading, ensure your trolling motor and wiring are compatible with lithium batteries, as they operate at higher voltages. A suitable charger specifically designed for lithium-ion technology is essential to maintain battery health. Proper installation and wiring are critical to avoid electrical issues. Lithium batteries provide a reliable power source, reducing the risk of unexpected shutdowns during extended use. Their durability and low maintenance make them a worthwhile investment for serious anglers seeking optimal performance and convenience.

Proper trolling motor wiring ensures safety, efficiency, and optimal performance. Refer to detailed guides, diagrams, and manufacturer resources for specific setups. Invest in quality components for long-term reliability and enhanced fishing experiences.

10.1 Summary of Key Points

Proper trolling motor wiring is crucial for safety, efficiency, and performance. Always use the correct wire gauge, ensuring it matches your system’s voltage and current requirements. Circuit breakers and fuses protect against overcurrent, while plugs and receptacles enable quick disconnects. Battery configuration depends on voltage needs, with series setups for higher voltage and parallel for increased capacity. Safety precautions, such as wearing protective gear and avoiding jewelry, are vital when handling batteries. Regular maintenance, including wire inspections and connection cleaning, prevents issues. Upgrading to components like PWM controllers or lithium batteries can enhance performance. Follow detailed guides and manufacturer instructions for specific setups. Investing in quality materials and adhering to best practices ensures reliable operation and extends system lifespan. Always prioritize safety to avoid electrical hazards and ensure optimal trolling motor functionality.

10.2 Recommended Reading and Resources

For a deeper understanding of trolling motor wiring, consult comprehensive guides like the Trolling Motor Wiring Guide by TrollingMotorsGuide.com. This resource covers voltage-specific setups, safety tips, and troubleshooting. Additionally, the Minn Kota Trolling Motor Manual and MotorGuide Trolling Motor Wiring Diagrams provide brand-specific instructions. For general boat wiring, Boat Electrical Wiring Made Easy is an excellent resource; Video tutorials on YouTube, such as those by Pro Wrenching, offer step-by-step visual guidance. Forums like Reddit’s r/boating and specialized Facebook groups are great for community advice. Always refer to manufacturer websites for precise wiring diagrams and safety protocols. These resources ensure a safe, efficient, and professional trolling motor setup, whether you’re a novice or experienced user.